Most additive manufacturing methods were designed for small scale prototype parts, but today the industry research is pushing towards larger scale manufacturing and stronger parts. Full scale cars and furniture have been printed with the constant challenge or time reduction and increased strength.

This reinforced printing nozzle allows the production of parts with a metal wire fed paralelle to the polymer Filament.

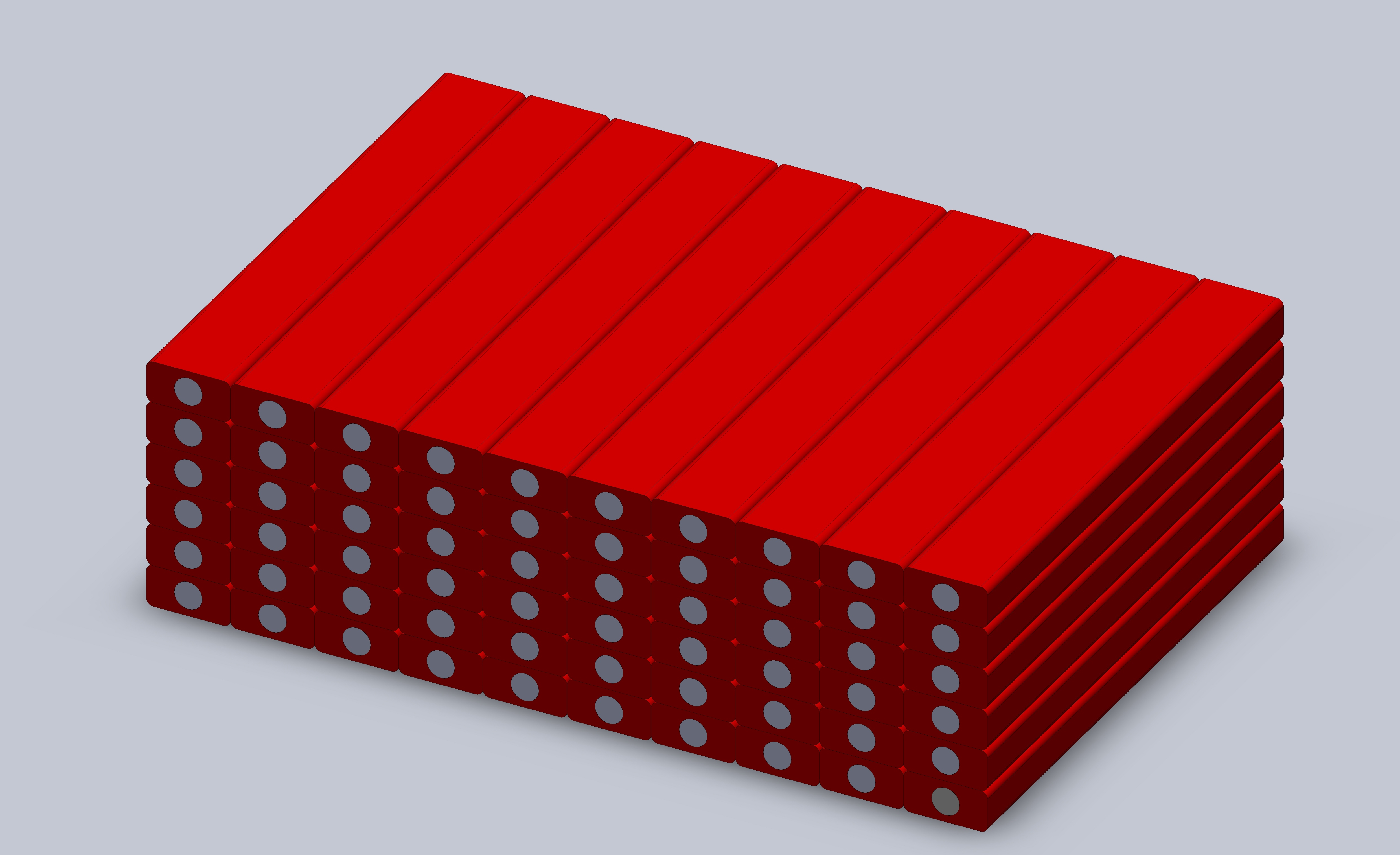

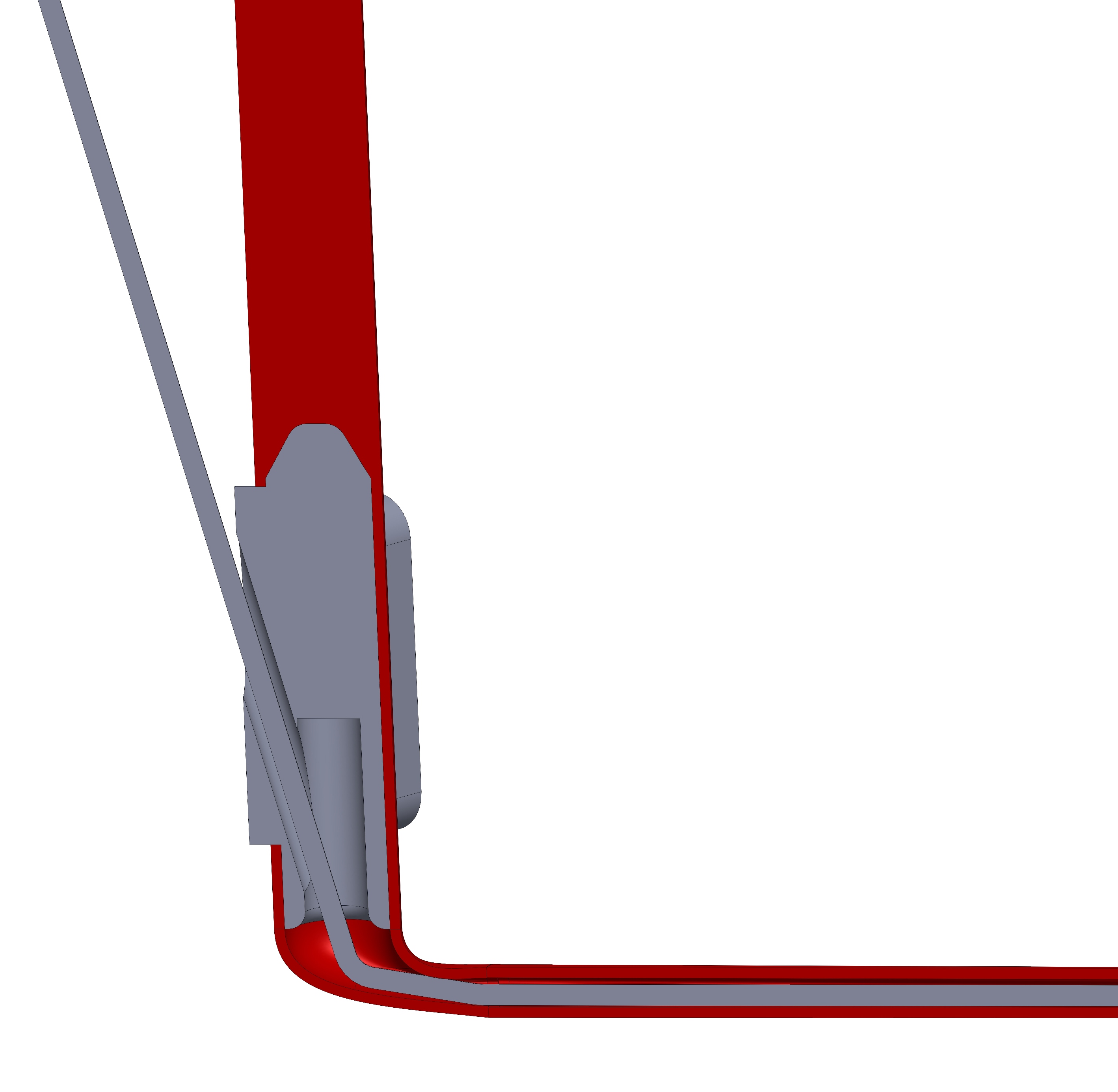

Inspired by profile extrusion technologies, this Concept nozzle uses a Standard design with an added insert. The insert shown below in Grey color allows the polymer to flow around it before reaching the hot end, and also allows through an Opening, a metal wire (or mesh) to be fed with the polymer.

Such adjusted nozzle design requires the grey insert and a special copper (or other) end with a hole at its side to allow the metal wire in.

Isolating the polymer in 3D view, you can see how the flow seperates into three streams and then connects again at the nozzle tip. The seperation of the polymer flow allow the polymer to heat faster as it increases the contact area with the nozzle.

Having this Special nozzle insert allows the increase of the extruded diameter or the final deposited width. Even without extruding a metal wire with the polymer, this nozzle can have a diameter much larger then the filament being fed. This feature is not possible with standard nozzles as the genral recommendation is a nozzle width of not more than half the filament diameter.

The last Picture above shows how the metal wire and the molten polymer meet before deposition. I think should Concept can have many application for large scale models and high strength requirements. The wire fed with the polymer can be of any other material including glass fiver and Carbon Fiber.

I would like to to know your opinion on such Concept ? Do you think there would be difficulty in printing ?