More than ten years of hype About the 3D printing Technology ,and it still faces the same Problems.Those Problems include , slow process, limited build volume, and reduced accuracy for larger parts.(properly named additive manufacturing)

The most common desk technology is the fused deposition manufacturing (FDM), this technology uses a plastic filament that is molten through a hot nozzle and deposited layer by layer to form a plastic part. Most printers in the market have a build area of 200x200 mm to 500x500 mm, with the larger Printers having less print accuracy and more problems with proper heat distribution on the heated bed.

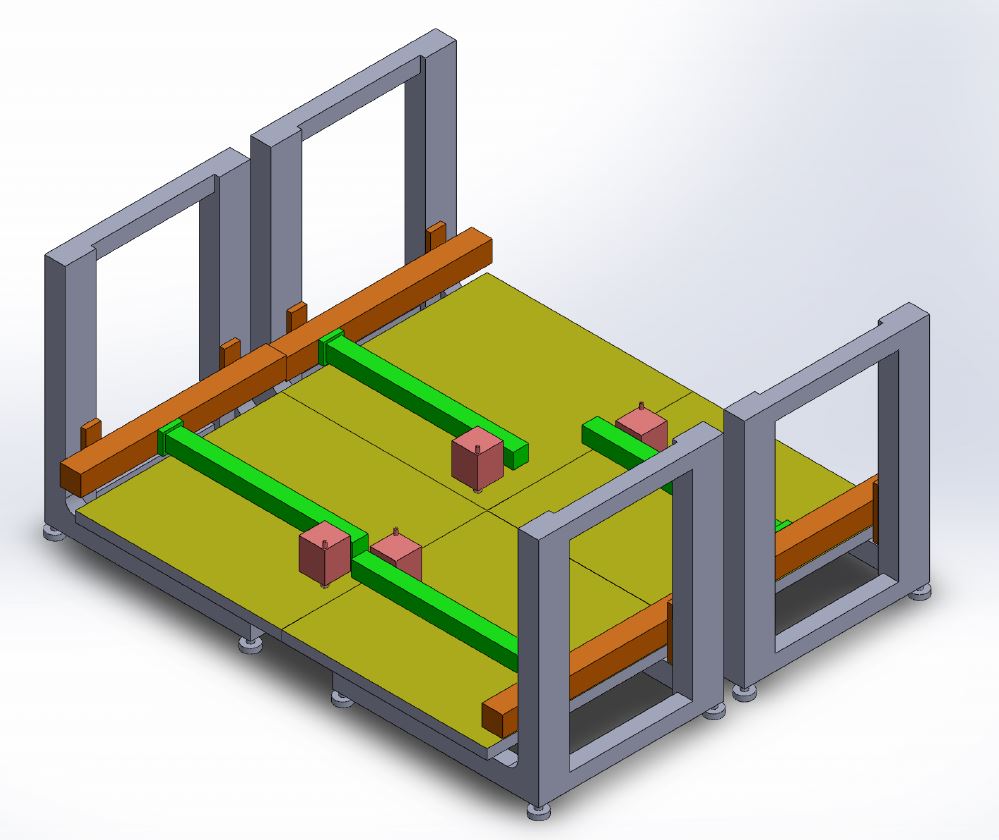

This is a simplified design of one cooperative Printer. This open side print bed combined with the possibility for the nozzle to travel few millimiters outside the build area, make this printer concept capable of depositing plastic on the build plate of an adjacent printer. so, why would that be usefull ?

The printer can deposite a brick shaped layout or in other words a Zipper form attached layers, so whatever part is being build on the adjacent build plate is connected to the part on the main printer. The attached parts will have a layer interface as shown below. With a thickness to length ratio of more than 15 the parts will be properly bonded with enough strength. Also the parts could have intentionally thicker walls on the interface zone.

Bringing several Printers together allows the designer to manufacture larger parts faster. Joining four cooperative Printers together allows the production of a four times larger volume, with the accuracy and the time requirement of a small printer.

Bringing several Printers together allows the designer to manufacture larger parts faster. Joining four cooperative Printers together allows the production of a four times larger volume, with the accuracy and the time requirement of a small printer.

Bringing several Printers together allows the designer to manufacture larger parts faster. Joining four cooperative Printers together allows the production of a four times larger volume, with the accuracy and the time requirement of a small printer.

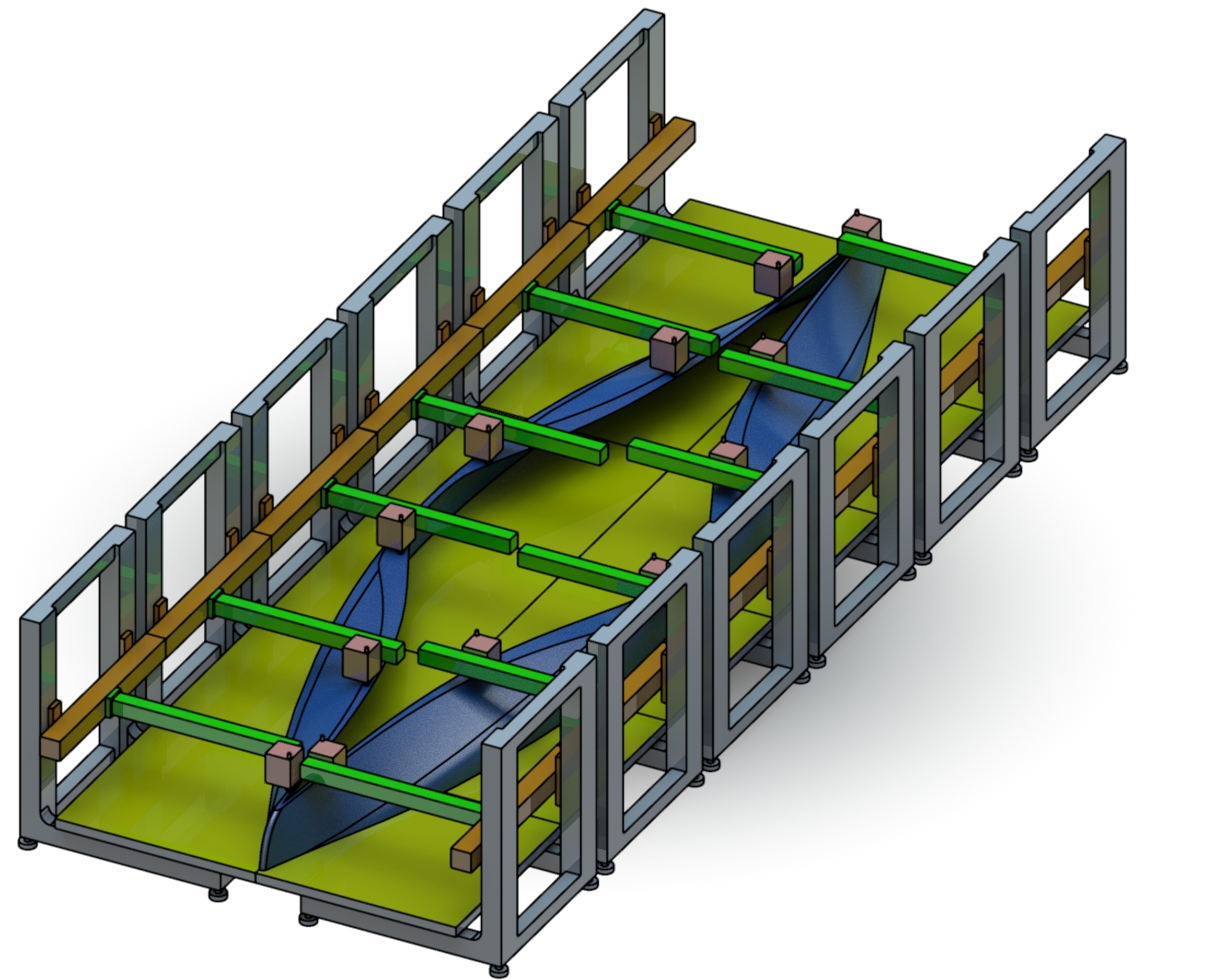

Bringing several Printers together allows the designer to manufacture larger parts faster. Joining four cooperative Printers together allows the production of a four times larger volume, with the accuracy and the time requirement of a small printer. There should be no Limit of how many Printers can be joined together at least in a side by side format with two opposed Printers. Long structures can be built in short time. For example structure beams and maybe a Kayak.

There should be no Limit of how many Printers can be joined together at least in a side by side format with two opposed Printers. Long structures can be built in short time. For example structure beams and maybe a Kayak.

One last thought on cooperative Printers Concept. If the builtd plates are totally detached from the structure Holding the nozzle and the nozzle structure can be attached to the ceiling of the printing room (Or a large structures that holds it from above) then the build plates can be assembeled in any form and on all four sides. There is no Limit on how large the total build area can be, while at the same time the more printers added the more nozzles are printing, and the manufacturing time does not increase. Only the build height is limited by the coopertative Printers concept.

The slicing software needs to be adjusted to add the zipper feature and generate a path for the nozzles so they do not print at the same location at the same time, and remain at a safe operating distance from other nozzles.

I would like to hear your opinion on this concept. Do you think it can work ? What ptoblems does it face ?

No comments:

Post a Comment